Technology in logistics timeline

In the early days, logistics companies faced many issues, such as low delivery speed, lack of security, and nonavailability of tracker systems. Moreover, logistics companies also face security problems.

Technology in logistics has revolutionized the logistics industry. Logistics is the backbone of modern businesses and the global economy. Logistics is used to transfer goods and resources from one place to another place. Technology in logistics has changed the way an important part of global commerce, and with the growth of technology, many changes have taken place. Businesses can deliver their goods to international markets with the help of logistics. Logistics can also be helpful in coordinating manufacturers, suppliers, and retailers throughout the world.

Logistics technology can help with various tasks, such as inventory management, warehousing, cost-effective distribution, and supply chain coordination. Thanks to logistics technology, accuracy, efficiency, and speed have improved. Artificial Intelligence Will Blend in with Humanity transforming industries and enhancing human capabilities

What is logistics?

Logistics refers to the movement of goods and resources from the point of production to the point of consumption or their final destinations. The main objective of logistics is to provide goods in a timely and cost-effective manner.

The importance of logistics in business

Logistics is always complex and depends on the nature of the business. However, efficient logistics can play an important role in a business’s success. Without it, companies cannot deliver goods.

The primary objective of logistics companies is to deliver goods to customers’ doorsteps. Advanced technology in logistics has caused an increase in efficiency, reduced costs, enhanced production rates, and improved inventory management. Efficient use of warehouses, higher client and vendor satisfaction. Logistics: Small-scale companies are also required to retain logistics to compete with large-scale businesses.

Real-time insights

Effective real-time insights enable the business to identify issues in the supply chain and allow management to take corrective actions.

Scalability

Efficient logistics technology helps businesses expand their operations and guides management in meeting customers’ expectations.

Cost-effectiveness

Efficient logistics technology enables businesses to minimize their logistics costs and analyze demand and supply curves. Thus, companies can save huge amounts of money on unnecessary logistics use.

The Evolution of Logistics Technology

Before the invention of logistics logistics technology, humans were used to transferring goods and supplies. However, technology has changed the way goods are moved. In the modern era, trucks are used to transfer goods and supplies.

Let’s discuss the evolution of the logistics industry.

Horse-Drawn Carriages and the Birth of Modern Logistics

Horse-drawn carriages were used to transfer goods from one place to another, but they were slow, limited to shorter areas, and labor-intensive. The Romans introduced land and sea routes for the transfer of goods. Stream-powered trains and logistics increased the efficiency and reach of delivery.

The Rise of Motorized Vehicles

In the early 20th century, trucks made the delivery system more efficient, fast, and secure. Logistics companies could deliver goods over short and long distances and in residential areas. Gottlieb Daimler created the first truck in history.

Containerization and Globalization

Malcolm McLean introduced containerization. Before containerization, break bulk shipping processes were used for loading and unloading goods. This method had some drawbacks, such as high cost, time consumption, and damage or theft of goods.

Containerization was a game-changer in the logistics industry. Standard containers enabled the industry to move intermodal transportation such as trains, ships, and trucks. Containerization has increased efficiency and reduced costs.

Information Technology and Tracking Systems

In the 20th century, logistics operations were integrated with information technology. Total cost management (TCM) analyzes the cost structure.

Barcode scanning, RFID technology, and GPS tracking track the real-time movement of goods. Advanced technology in logistics operations increases efficiency and reduces costs.

Automation and Autonomous Vehicles

Automation has made logistics operations more efficient and cost-effective. Warehouse automation and robotic systems for order fulfillment are necessary components of today’s logistics system.

The installation of advanced sensors in autonomous vehicles and artificial intelligence improved safety and streamlined processes.

Predictive Analytics and Machine Learning

Predictive analytics and machine learning have optimized routes, increased operational efficiency, and predicted demand patterns. These technologies also enable logistics companies to make better decisions, reduce costs, and become more eco-friendly.

Drones and Last-Mile Delivery

Drones enable the logistics industry to deliver packages to more congested or remote areas. The industry is working hard to integrate drone technology with logistics operations, which will make the delivery system more efficient.

Artificial intelligence and automation will lead the logistics industry toward more innovation.

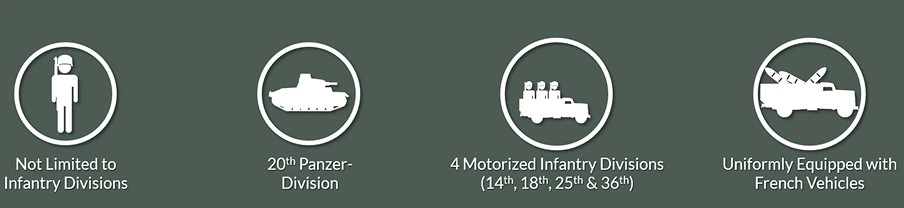

Logistics history and background

In the 13th century, the Mongol cavalry was famous for its efficient logistics system. At that time, logistics was used to move army troops from one place to another. The army was divided into various troops, and cattle, pack animals, and baggage carts were used to transport the military.

Napoleon introduced storage depots containing supplies and rolling magazines that were used to carry supplies for a few days.

In the 1800s, transportation was done using humans and horses. There was no system or administration to manage goods in the godown or warehouse. It was difficult to follow the delivery process and ensure that goods arrived on time. The logistics process was slow, and there were no technologies to speed it up.

The history of logistics starts with human civilization. The Egyptian empire (330 BCE to 332 BCE) introduced storage and transportation techniques in order to maintain a supply of goods and basic commodities.

Later on, the Roman Empire (27 BCE to 476 BCE) introduced Roman roads to expedite the troops and transportation of goods in its territory. In the beginning, the Romans used convoy ships for sea transport and established depots along with their routes. At that time, trade routes were introduced to connect Europe and Asia. These routes facilitate the transportation of goods, knowledge, metals, fabrics, and species among various regions of the world. The Silk Road was the main commercial route for trade between East and West countries.

The early 1900s ( the beginning of modern)

In ancient times, there were limited resources to move goods and services in a timely and efficient manner. Logistics was a manual procedure. Logistics has been dominant and key ever since humans and animals used it to transport goods and services. However, these methods were limited in their speed to reach the destination, which was more time-consuming.

Logistics has been a long journey, from loading goods on horses to using heavy trucks.

In 1913, Henry Ford introduced the concept of assembly line production, and the mass production of automobiles revolutionized logistics management.

Because goods were produced on a large scale, demand for transportation and streamlined distribution networks increased. The mass production concept required rapid growth in logistics systems, such as planning coordination and efficient delivery systems. Timely delivery of goods became essential to meet customer demands and maintain the production schedule.

The introduction of trucks, railroads, and improved roads has made goods delivery longer and more efficient. Advancements in transportation infrastructure have also improved the distribution of goods among manufacturing plants, warehouses, distribution centers, and ultimate customers.

The Era of Military Logistics (the 1940s-1970s)

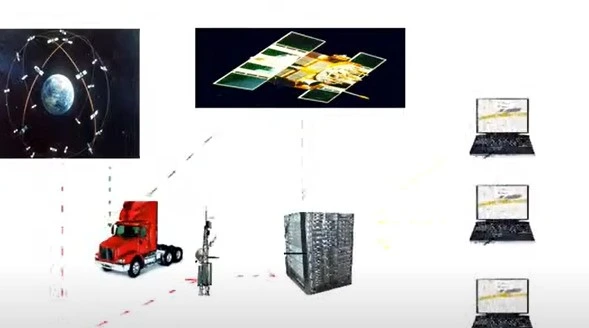

GPS technology in logistics improved supply chain management, coordination of military operations, and efficient delivery of equipment and supplies to military troops. GPS has revolutionized transportation and supply chain management.

Now, GPS can monitor the real-time movement of goods and optimize transportation routes. Thus, the transportation system can deliver goods efficiently and effectively.

The integration of GPS into commercial logistics has brought efficiency, reduced costs, and improved customer service. GPS technology in logistics can better utilize resources, reduce fuel consumption, and optimize routes. It also caters to the facility to provide estimated arrival time and fast and reliable delivery.

The 1980s-1990s: The Era of Logistics Outsourcing

In the 1980s and 1990s, logistics service provider companies emerged and took over the logistics operations of large companies. Now, these companies can focus on their core business operations, and logistics specialists handle logistics operations.

Outsourcing benefits

With the help of outsourcing, companies are able to reduce costs and maximize their profits by achieving economies of scale.

No need to invest in heavy infrastructure, warehouses, and transportation.

Companies’ efficiency has improved with outsourcing.

Satisfied customers with the help of timely delivery of parcels

The Internet Era: ERP System And GPS (the 1990s)

ERP System

Enterprise resource planning systems (ERPs) are software that connects logistics with other main business modules, such as manufacturing, operations, accounting, resource management, etc.

ERP is a type of software that different organizations use to achieve optimal performance.

GPS Technology

The Global Positioning System (GPS) is a satellite navigation system that helps track the movement and location of deliverable goods. GPS technology in logistics increased operational efficiency and reduced costs as well.

E-Commerce and Logistics

All e-commerce businesses heavily rely on logistics. Retailers like Amazon devote a significant amount of their budget to growing the logistics industry so that goods can be delivered swiftly and conveniently.

Automation And Robotics In Logistics (2000s-Present)

As we enter the 21st century, logistics logistics technology is evolving rapidly, consequently increasing efficiency in the industry. Recently, machines and robots have made a big difference by helping the industry in multiple ways. Robots and machines help organize warehouses and track products. They make all processes reliable and accurate, saving time and reducing the chance of mistakes.

Automation in the Warehouse

Warehouse automation uses advanced methods to store, pick, and ship goods. Automated Guided Vehicles (AGVs) and robots work with humans to make their lives easier and process things faster and more accurately. Some warehouses that store bulk goods use drones to check and count inventory.

Robotic Pickers

Robotic pickers are robots that different distribution centers or warehouses use to pick products and pack them on their own. Robots reduce the labor costs of human workers; one advantage of robots is that they are faster, save time, and reduce labor costs. They reduce the need for human workers. We only give one command to the robots; in fact, commands are also embedded in the buttons. We just have to click the corresponding button, and work will be done automatically.

Drones and Autonomous Delivery

Big companies like Amazon are testing drones to deliver products. Google’s Wing is also testing drones for autonomous delivery systems to speed up the logistics process. If drones help with delivery, they can reduce the cost and delivery time. Thus, customers will benefit from faster and more convenient service.

The 2000s-2010s: The Rise of E-commerce Logistics

Once again, the internet and e-commerce have transformed logistics. E-commerce has transformed consumers’ shopping habits. No one has time to visit the market and buy some items. Online shopping has increased customers’ expectations of instant delivery. As a result, logistics companies need to adopt the latest technology in their operations.

Logistics companies take many steps to overcome these issues, like introducing advanced technology in warehouse automation, route optimization algorithms, and real-time tracking systems.

These measures enable logistics companies to process orders quickly, manage inventory efficiently, and deliver orders on time. Logistics companies also introduced the innovative last-mile delivery system, locker system drone deliveries, and partnerships with local courier service providers.

They also try to meet customer expectations, such as same-day or next-day delivery of their orders.

There are three pillars of e-commerce logistics: storage, information systems, and last-mile delivery.

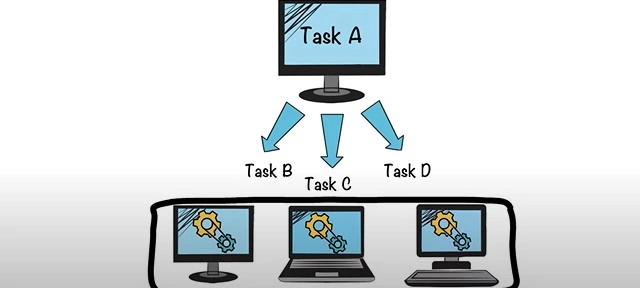

Artificial Intelligence And Big Data in Logistics (the 2010s-2017s)

Artificial intelligence and big data technology add a lot to the logistics timeline. Businesses can scan and analyze data more quickly with the help of these technologies. They help companies plan efficient delivery routes, better inventory tracking, and improve customer service.

Improved competence and decision-making revolutionized supply chain operations. Artificial intelligence (AI) remarkably enhances quality control processes in the supply chain, increasing the correctness and speed of procedures and resulting in a better experience for customers and businesses. Businesses must adopt AI to compete in the logistics industry.

Demand Forecasting and Route Optimization

These AI bots analyze data and process information, generating plans to adjust inventory levels, optimize delivery routes, minimize fuel costs, save delivery time, and manage fleets.

AI informs logistics companies of vehicle routes and conditions in real-time. It also alerts companies if any of their vehicles are faulty so they can fix them on time before they cause problems.

Big Data in Supply Chain Visibility

Big data allows logistics companies to monitor every step of the entire supply chain. Managers collect clear data from different sources. The clear visibility of every step in the logistics supply chain allows all managers to track shipments, count inventory, and monitor how delivery companies and suppliers transport goods.

Blockchain Technology: Enhancing Transparency and Security in Logistics (2017–present)

Blockchain technology in logistics has become very popular. It allows record-keeping security, transparency, and traceability in the logistics sector. Blockchain is decentralized by nature. Decentralization allows all parties to access the same accurate, real-time information or data to eliminate fraudulent activities.

Blockchain for Supply Chain Transparency

The blockchain generates stable and immutable reports of each step during a product’s shipment. When a product moves from the manufacturer to the warehouse and then to the customer, all these steps are recorded. Blockchain caters to true and transparent records that every stakeholder can access. The security that a blockchain provides is especially important for food.

Smart Contracts for Faster Transactions

Financial firms use smart contracts to employ digital tokens to represent tangible assets. Artificial intelligence-powered smart contracts are the key to a brighter future. Many hitherto stable marketplaces may become unstable if smart contracts start to include artificial intelligence. Autonomous software running on a blockchain is called a smart contract.

Future of Logistics – 2023 and Beyond

Since its creation, the logistics sector has progressed through many stages of growth. It is highly capable of further innovation and advancement. Logistics is expected to adopt greater automation, eco-friendly supply chains, and robotics.

Logistics 4.0 Various automation software, like RFID barcodes and tracking systems, were introduced to make logistics operations more efficient and effective.

Logistics 5.0 is trying to provide new values with the help of artificial intelligence.

Advanced technology in logistics helps businesses to attain a competitive advantage.

The future of logistics depends on efficiency, sustainability, innovations, and investment in new technology.

Sustainability and Green Logistics

New packaging envelopes are being created that do not harm the environment when discarded. Some firms are even producing envelopes that, when thrown away, release seeds that grow into plants.

Shorter routes will be used to deliver products, saving fuel and lowering carbon footprints. Batteries are currently employed in cars, and the usage of hydrogen-powered trucks is likely to rise. This will help reduce hazardous emissions from the logistics sector.

Companies are also working to make warehouses more environmentally friendly. To lessen their negative environmental impact, they are installing solar panels and water recycling.

Emerging technologies in logistics

Cloud logistics

About 70% of companies are trying to use cloud computing technology in the future. Cloud computing is used to control warehouse operations. A warehouse management system is required to use cloud logistics. It offers facilities more flexibility and security, low initial investment, multi-location warehouse management, and real-time stock visibility.

The Role of AI in Logistics

Artificial intelligence is used to automate routine tasks. With the help of artificial intelligence, logistics businesses are able to reduce costs, improve efficiency, and better customer service management. Artificial intelligence also enables logistics companies to make efficient decisions.

Internet of Things

Sensors, connectivity, and data analytics are major components of the Internet of Things. The main objectives of IoT are real-time tracking, inventory management, vehicle tracking, and driver behavior monitoring.

Virtual reality and digital twins

A digital twin is a virtual representation of physical processes, assets, and objects. IoT data, such as sensors, artificial intelligence (AI), and other technologies, is used to create digital twins. These twins help companies analyze performance and make decisions accordingly.

Conclusion

Humans and horses were used to move goods from one place to another. Later, trucks made logistics operations more efficient and cost-effective. Technology in logistics can change every field of life, including logistics operations.

The e-commerce industry also recognizes the importance of efficient logistics, as customers are required to receive their parcels instantly. Therefore, logistics companies must adopt advanced technology in their operations and optimize their routes. With the help of logistics technology, logistics companies can effortlessly track the movement of goods.

Artificial intelligence (AI) has considerably enhanced the efficiency of the logistics industry. Artificial intelligence (AI) helps businesses reduce costs, optimize routes, and improve customer service management. It also allows businesses to meet the expectations of customers. Thanks to technology, days-long tasks can now be completed in minutes. The use of AI and robots virtually eliminates the likelihood of mistakes in work. The logistics industry will see fresh developments in the future.

Frequently asked questions

Q1. What is technology in logistics?

Ans. Technology in logistics means the timely delivery of goods to customer’s doorsteps. The use of technology in logistics reduces costs, increases efficiency, and improves customer satisfaction.

Q2. What is the new technology in logistics?

Ans. In the modern world, artificial intelligence is swiftly changing old technology. The new era will be artificial intelligence. Artificial intelligence increases the efficiency of logistics operations.

Q3. What is technology integration in logistics?

Ans. The integration of technology in logistics caters to the facility to reduce delays and improve customer satisfaction. Due to the usage of technology in logistics, businesses can analyze real-time data and make decisions accordingly.

Q4. What is the biggest influence technology has had over logistics?

Ans. Technology helps to implement blockchain technology in the logistics industry. Blockchain technology helps to make secure and transparent transactions. It can be helpful to track the movement of goods.

Q5. What is the future of logistics?

Ans. Technology in logistics is swiftly changing the logistics industry. It optimizes the routes, increases efficiency, and tracks the movement of goods.

The use of artificial intelligence is helpful in meeting customer’s expectations.

Q6. How is AI used in logistics? Ans. Artificial intelligence helps businesses to optimize logistics operations. It can reduce costs, track the movement of goods, and automate logistics operations.